-

Stainless Steel Round Pipe

-

Stainless Steel Welded Pipe

-

Stainless Steel Seamless Pipe

-

Carbon Steel Pipe

-

Galvanized Steel Pipe

-

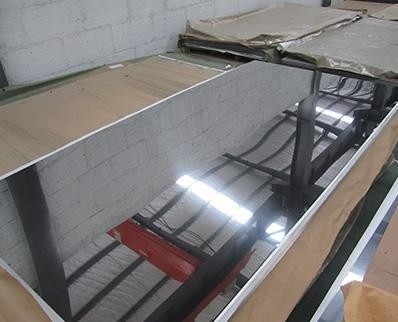

Stainless Steel Sheet Plate

-

Angle Steel Profile

-

Stainless Steel Round Bar

-

Aluminum Alloy Sheet

-

Stainless Steel Coil

-

Galvanized Steel Sheet

-

Copper Tube Pipe

-

Copper Alloy Plate

-

Copper Strip Roll

-

Aluminum Alloy Foil

-

Tinplate

-

Other Alloy Metals

-

Rectangular Steel Pipe

20 Gauge 26 Gauge 22 Gauge 201 Stainless Steel Sheet Grade 430 Ss Plate

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Stainless Steel Sheet Plate | Type | SS Tube |

|---|---|---|---|

| Length | 2000/2438/2500/3000/3048 Mm | Width | 1000/1219/1250/1500 Mm |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting | Delivery Time | 7-15 Days |

| Surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D | ||

| High Light | Vespolari 430 stainless steel plates,Vespolari 430 ss sheets,Vespolari ss 430 stainless steel sheets |

||

430 stainless steel sheet

Type 430 Stainless Steelis a low carbon ferritic stainless steel which, in mildly corrosive environments or atmospheric exposures, has corrosion resistance approaching that of some nickel-bearing stainless steels.

Online consultationProject Introduction

Type 430 Stainless Steelis a low carbon ferritic stainless steel which, in mildly corrosive environments or atmospheric exposures, has corrosion resistance approaching that of some nickel-bearing stainless steels. This alloy is oxidation resistant at elevated temperatures. Type 430 is ductile, does not work harden readily, and can be formed using a variety of roll forming or mild stretch bending operations as well as the more common drawing and bending processes. Type 430 is ferromagnetic.

Specifications

ASTM A240

Typical Applications

Sinks, sink rims, appliance trim, counter tops, dish washers, range hoods, flatware, architectural uses, roofing, siding and restaurant equipment.

Chemical Composition

|

Element |

Type 430 |

|

Carbon |

0.12 max. |

|

Manganese |

1.00 max. |

|

Sulfur |

0.030 max. |

|

Phosphorus |

0.040 max. |

|

Silicon |

0.75max. |

|

Chromium |

16.0 18.0 |

|

Nickel |

0.60max. |

Mechanical Properties

|

Type |

Yield Strength 0.2% offset (KSI) |

Tensile Strength (KSI) |

% Elongation (2" Gauge length) |

Hardness Rockwell |

|

430 Ann |

30 min. |

65 min. |

22 min |

HRB 89 |

Physical Properties

|

Density (lb./ in^2) @ RT |

0.278 |

|

|

Modulus of Elasticity in Tension (psi x 10^6) |

29.0 |

|

|

Specific Heat (BTU/°F/lb.) |

32 to 212 °F |

0.11 |

|

Thermal Conductivity (BTU/hr/ft^2/ft) |

212°F |

13.8 |

|

932°F |

15.0 |

|

|

Mean Coefficient of Thermal Expansion (in. x 10^-6 per °F) |

32 to 212°F |

5.7 |

|

32 to 932°F |

6.2 |

|

|

Electrical Resistivity (micro ohms - cm) |

at 70°F |

60.0 |

|

Melting Point Range (°F) |

2600 - 2750 |

|

|

Oxidation Resistance - Continuous Service(°F) |

1500 |

Processing

Type 430 should be annealed at 1450-1550F and furnace cooled at a rate of 50°F per hour to 1100°F and air cooled. If the annealing temperature does not exceed 1450°F (790°C), an air cool may be substituted for the furnace cool when annealing thin sections.

Forming

Type 430 is readily drawn and formed. Its drawing characteristics are similar to those of low-carbon steel, although it is stronger in the annealed condition and will require stronger tooling and increased power.

Welding

Type 430 is generally considered to be weldable by the common fusion and resistance techniques. Special consideration is required to avoid brittle weld fractures during fabrication. When a weld filler is needed, AWS E/ER 308L and 430 are most often specified. Corrosion: This alloy is resistant to attack in a wide variety of corrosive media including nitric acid, and many organic acids.