-

Stainless Steel Round Pipe

-

Stainless Steel Welded Pipe

-

Stainless Steel Seamless Pipe

-

Carbon Steel Pipe

-

Galvanized Steel Pipe

-

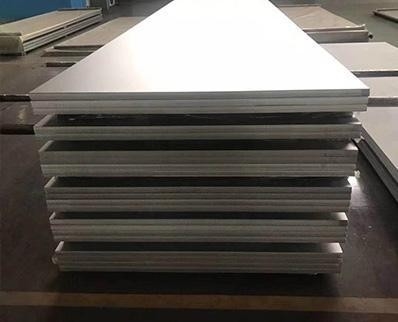

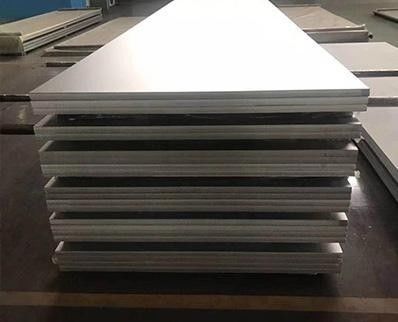

Stainless Steel Sheet Plate

-

Angle Steel Profile

-

Stainless Steel Round Bar

-

Aluminum Alloy Sheet

-

Stainless Steel Coil

-

Galvanized Steel Sheet

-

Copper Tube Pipe

-

Copper Alloy Plate

-

Copper Strip Roll

-

Aluminum Alloy Foil

-

Tinplate

-

Other Alloy Metals

-

Rectangular Steel Pipe

30 Gauge 20 Gauge 304 18 Gauge Stainless Steel Sheet Metal 4x8 2m X 1m 30 X 30

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Stainless Steel Sheet Plate | Type | SS Tube |

|---|---|---|---|

| Length | 2000/2438/2500/3000/3048 Mm | Width | 1000/1219/1250/1500 Mm |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting | Delivery Time | 7-15 Days |

| Surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D | ||

| High Light | 18 gauge stainless steel sheet 4x8,19 gauge stainless steel sheet,20 gauge 304 stainless steel sheet |

||

316L stainless steel plate

It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components.It also applies to food, beverage packaging, kitchen supplies, trains, aircraft,conveyor belts, vehicles, bolts, nuts, springs, and screen.

Chemical Composition: ASTM A240, A666

|

Element |

Type 316 |

Type 316L |

|

Carbon |

0.08 max. |

0.030 max. |

|

Manganese |

2.00 max. |

2.00 max. |

|

Sulfur |

0.030 max. |

0.030 max. |

|

Phosphorus |

0.045 max. |

0.045 max. |

|

Silicon |

1.0max. |

1.0max. |

|

Chromium |

16.0 18.0 |

16.0 18.0 |

|

Nickel |

10.00 14.00 |

10.00 14.00 |

|

Molybdenum |

2.00 3.00 |

2.00 3.00 |

|

Nitrogen |

0.10 max. |

0.10 max. |

Mechanical Properties: ASTM A240

|

Type |

Yield Strength 0.2% offset (KSI) |

Tensile Strength (KSI) |

% Elongation (2" Gauge length) |

Hardness Rockwell |

|

316 |

30 min. |

75 min. |

40 min. |

HRB 95 max. |

|

316L |

25 min. |

70 min. |

40 min. |

HRB 95 max. |

Physical Properties:

|

Density (lb./ in^2) @ RT |

0.29 |

|

|

Modulus of Elasticity in Tension (psi x 10^6) |

28.0 |

|

|

Specific Heat (BTU/°F/lb.) |

32 to 212 °F |

0.12 |

|

Thermal Conductivity (BTU/hr/ft^2/ft) |

212°F |

9.4 |

|

932°F |

12.4 |

|

|

Mean Coefficient of Thermal Expansion (in. x 10^-6 per °F) |

32 to 212°F |

8.9 |

|

32 to 600°F |

9.0 |

|

|

32 to 1,000°F |

9.7 |

|

|

32 to 1,200°F |

10.3 |

|

|

Electrical Resistivity (micro ohms - cm) |

at 70°F |

29.4 |

|

Melting Point Range (°F) |

2500 - 2550 |

Processing

Types 316 and 316L are non-hardenable by heat treatment. Annealing: Heat to 1900 - 2100°Fthen rapidly quench Forming: Types 316 and 316L can be readily formed and drawn.

Welding

These alloys are generally considered to have poorer weldability than Types 304 and 304L. A major difference is the higher nickel content for these alloys which requires slower arc welding speed and more care to avoid hot cracking. When filler is needed, AWS E/ER 316L and 16-8-2 are most often specified.

Corrosion

Types 316 and 316L Stainless Steels exhibit better corrosion resistance than Type 304. They provide excellent pitting resistance and good resistance to most chemicals involved in the paper, textile and photographic industries.